Applicators

High Volume Applicators

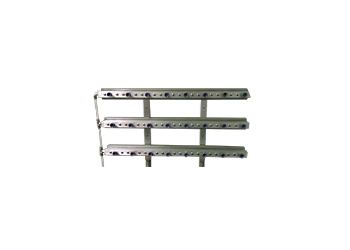

These applicators are well suited to high flows, high viscosities, high pressures, and hazardous locations.

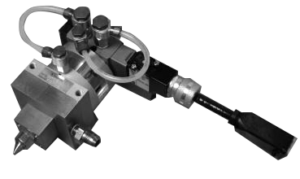

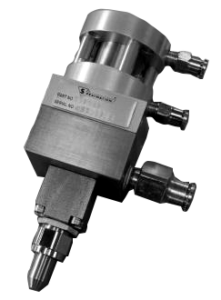

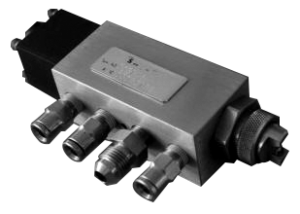

Spraymation Air Operated Electromatic™ Applicator Heads are extremely fast, and perform accurately and repeatably. It is “air open and closed” to assure rapid operation and clean pattern start-up and cut-off. Spraymation designs differ from most others. All seals are spring loaded graphite filled Teflon for long high speed life. All wetted parts are stainless steel or Teflon. The proven Spraymation seat and needle geometry are also used.

- Highest flow units have orifices sizes of .25 inch (6.3mm) for very high flow rates.

- Models are available for operating pressures to 5,000 PSI (340Bar).

- They are well suited to high viscosity materials.

- Various tips and nozzles are available.

- A intermediate series is available with orifice size of .125 inch ( 3.1 mm).

- This applicator is designed for a number of high speed industrial applications at pressures to 3,000 PSI (200 Bar).

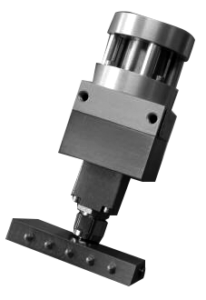

- Tips and spreading bars are available for coating wide materials

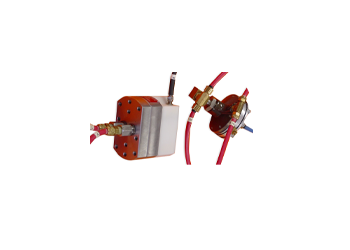

- Air operated extrusion applicator with .03 or ,05 orifice.

- This is commonly used with any of Spraymation’s large selection of tips and nozzles.

- This is a very high speed applicator capable of 2,500 PSI (170 Bar) and works well with high viscosities.

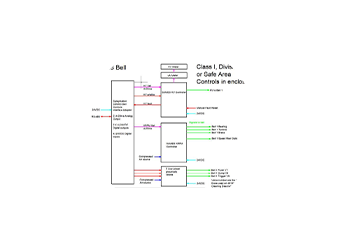

- It is commonly used in applications dispensing flammable fluids where an explosion hazard may be present.

- Air Atomizing spray applicators are also available that use all of the standard fluid tips and air caps used in the other Electromatic™ products.