Panel Machines

Integrating Bell Atomizer Controls with

Integrating Bell Atomizer Controls with

Spraymation Panel Machine

- Accurate High Voltage settings (KV) and Bell speeds (KRPM) can be embedded in your painting scripts.

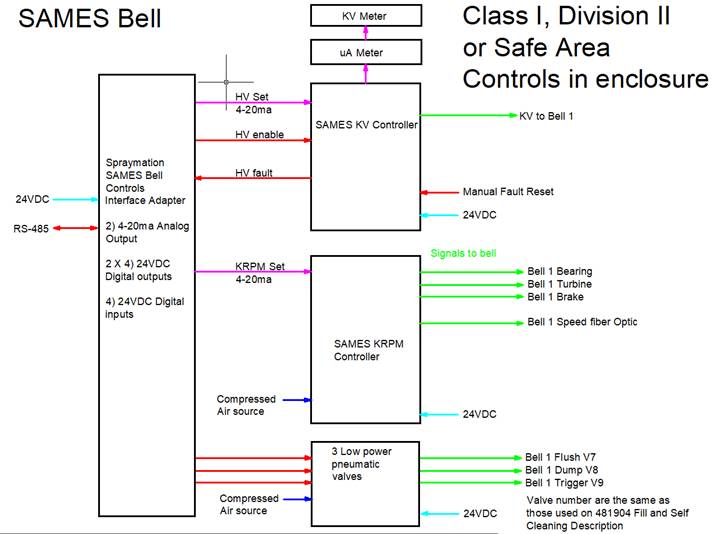

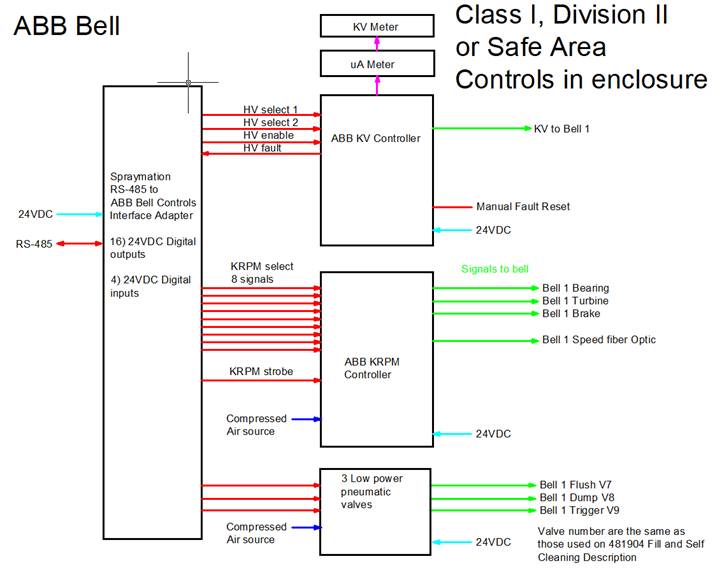

- Spraymation makes a series of Interface Adapters that are tailored to a specific set of customer-provided bell controls manufactured by the bell’s manufacturer.

- The KV and KRPM are set from the painting script. They can change from program to program automatically. They can be programmed to change between coats — more control of these spray parameters and less dependence on the technician making manual settings.

- The Interface Adapter provides the proper interface signals to set the high voltage and bell speed. Along with this enable signals are provided. Often pneumatic signals are also needed to control valves internal to the bell atomizer such as trigger, flush or dump. These valves can be controlled by the Interface Adapter.

- Spraymation will modify or select an Interface Adapters that mates with the controls the user has. They will need to provide Spraymation with the interface information from the equipment manufacturer.

- An RS-485 interface that is intrinsically safe is used to transfer commands from the Spraymation panel machine to the bell controller, so no large cables or conduit is needed. Also being able to provide the control pneumatic signals with the other controls needed for the operation of the bell in a safe or Class I, Division II area minimizes the interconnecting hoses coming from several points.

- We are often asked why we can’t provide a universal High voltage and speed control. When a bell atomizer is purchased with the manufacturer’s control units, they have taken the necessary steps to ensure when that atomizer is used with those control units the explosion-proof environment. We believe that a bell and its cascade voltage multiplier are only approved when used with the original controls from the bell’s manufacturer.